Bill Stuntz

Well-known member

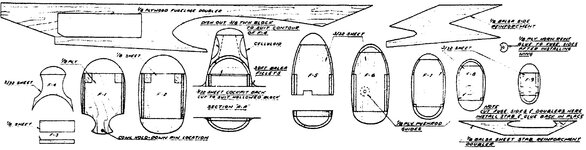

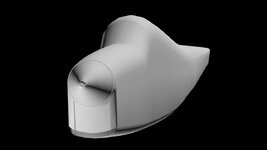

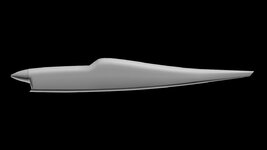

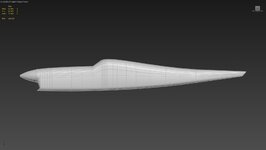

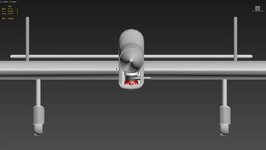

Looks great to me! Maybe feather fhe top/bottom curves into the flat sides a little more. There's actually a slightly sloped upper sheet above the flat sides behind the cockpit, making it pretty much egg shaped, fat end down. The actual flat fuselage sides are completely below the level of the cockpit. The flat sides feather into the curves as shown in the attachment. Did I send you the full plans, way back when? And there should be a little overhang at the top of the windshield - most visible in the "Santa2" photo above. I assume you 'll be hollowing out the area behind the rear cockpit bulkhead to resemble the cowl air outlets when you do them. Am I being too picky? I couldn't do what you've already done in a month of Sundays.